News

Our news desk will publish interesting articles about Cirrus Laser, it's projects and clients.

Cirrus Laser celebrates the Platinum Jubilee

10th May 2022

The Cirrus Laser factory will be closed for the Queen's Platinum Jubilee celebration extended weekend

Falling in line with the nation's countrywide Platinum Jubilee celebration, the Cirrus Laser factory will close at 5pm on Wednesday 1st June and reopen on Monday 6th June at 7am.

What a fantastic and historic milestone this is for Queen and Country, and all at Cirrus Laser raise a virtual glass to celebrate with the Royal Family and the British population.

ISO 9001:2015 certification

27th April 2022

After some hard work and collaboration we are pleased to confirm our ISO9001:2015 certification.

Last year during the pandemic Cirrus Laser successfully gained the renewal of the ISO 9001:2015 certification through Alcumus ISOQAR and is now fully compliant until January 2024.

A lot of hard work goes into this heavily governed process and it goes a long way to quantifying the quality of the service and the products that we as a company provide to our customers and clients.

If you have any further questions about how this certification was secured, please do not hesitate to contact our sales office.

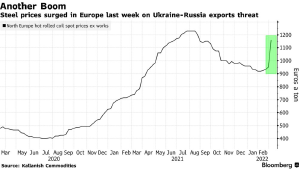

Ukrainian conflict causes material prices to soar

10th March 2022

We are noticing huge rises in the price of materials following the awful situation in Ukraine.

During Wednesday last week we obtained a price for 5mm S275 P&O steel from our usual hot rolled steel supplier and 48 hours later the sheet had increased by £17 each sheet. On Thursday last week 6mm S275 P&O was priced, by the same supplier and 24 hours later the sheet had increased by £14 each sheet, all of these sheet sizes were 2500 x 1250mm.

Although mild steel has been reducing in price for the past few months we now have the Russian / Ukraine factor where imported slab has been cut to zero due to the Russian invasion of Ukraine. About 40% of carbon steel slab used in the UK is imported from Russia and Ukraine, the reduction in slab availability and the lack of basic steel manufacture in the UK has put pressure on the availability of rolled steel products and hence the price per tonne. Slab is by far the biggest imported product from Russia and Ukraine and this will be for UK rolling mills to manufacture into HR coil/sheet or plate.

Cold rolled steel products (CR4) have also been affected this week with 3mm thick CR4 increasing by 22%, availability and price of CR4, zintec and galvanised steel will be affected in similar manner to hot rolled products, although unknown where basic steel for cold rolled products is sourced.

For many years we have purchased aluminium shate at about £2.60 to £2.80 per kilogramme, this increased in November 2021 to £4.56 per kilogramme but due to magnesium surcharge will now be imported and charged at £5.07 per kilogramme in March 2022. The 3 biggest suppliers of magnesium are China, Russia and Brazil. China has reduced magnesium production because of available electrical power, the manufacture of magnesium uses large amounts of power. We all know why Russia will not be exporting magnesium. It is inevitable aluminium prices will increase (due to magnesium content) and availability will be compromised. Stainless steel and copper alloys are also likely to have supply problems.

Our single biggest supplier of hot rolled steel sheet and plate has sold as much product in the first 7 days of March as they usually sell in the whole of March. This is due to panic buying of all types of steel products, this week they have stopped accepting further orders until they have de-coiled, cut and delivered existing orders. Our quotes for mild steel products are only valid for the day on which we prepare the quote. Unfortunately we will have to revise our price when customer orders are acknowledged, price and availability of steel products changes on a daily basis. Obviously price and availability of sheet and plate products is volatile and we ask customers to understand the reasons for these unprecedented supply issues.

News Archive

ISO 9001: 2015 Certified